Cover Plates

Some Tracks require the fabrication of a cover plate to capture the junction between 3 or more channels within a Track. Examples of this include [MD1], [J60], [CB], etc.

Cover Plates should ideally be clear or translucent so that you can see the movement of marbles within the Track. There are two ways to fabricate these cover plates depending on the digital fabrication tools you have available at your disposal -

-

CNC Laser Cut Cover Plates

A CNC Laser Cutter is the ideal way to fabricate your own cover plates. We recommend clear or translucent acrylic in a nominal thickness of 1-2mm for the fabrication of all cover plates unless otherwise specified. All Tracks that require cover plates have an included .DXF file for laser cutting.

Note

All TrackStacker .DXF files are exported in mm units

TrackStacker Labs uses iridescent acrylic in a 1mm nominal thickness for all in-house Track production.

-

3D Printed Cover Plates

If you do not have access to a CNC Laser Cutter, you can easily print your cover plates in clear PLA or PETG using the included cover plate .stls. Though not optically clear like laser cut cover plates, printed cover plates can provide a nice diffused translucent look to Tracks.

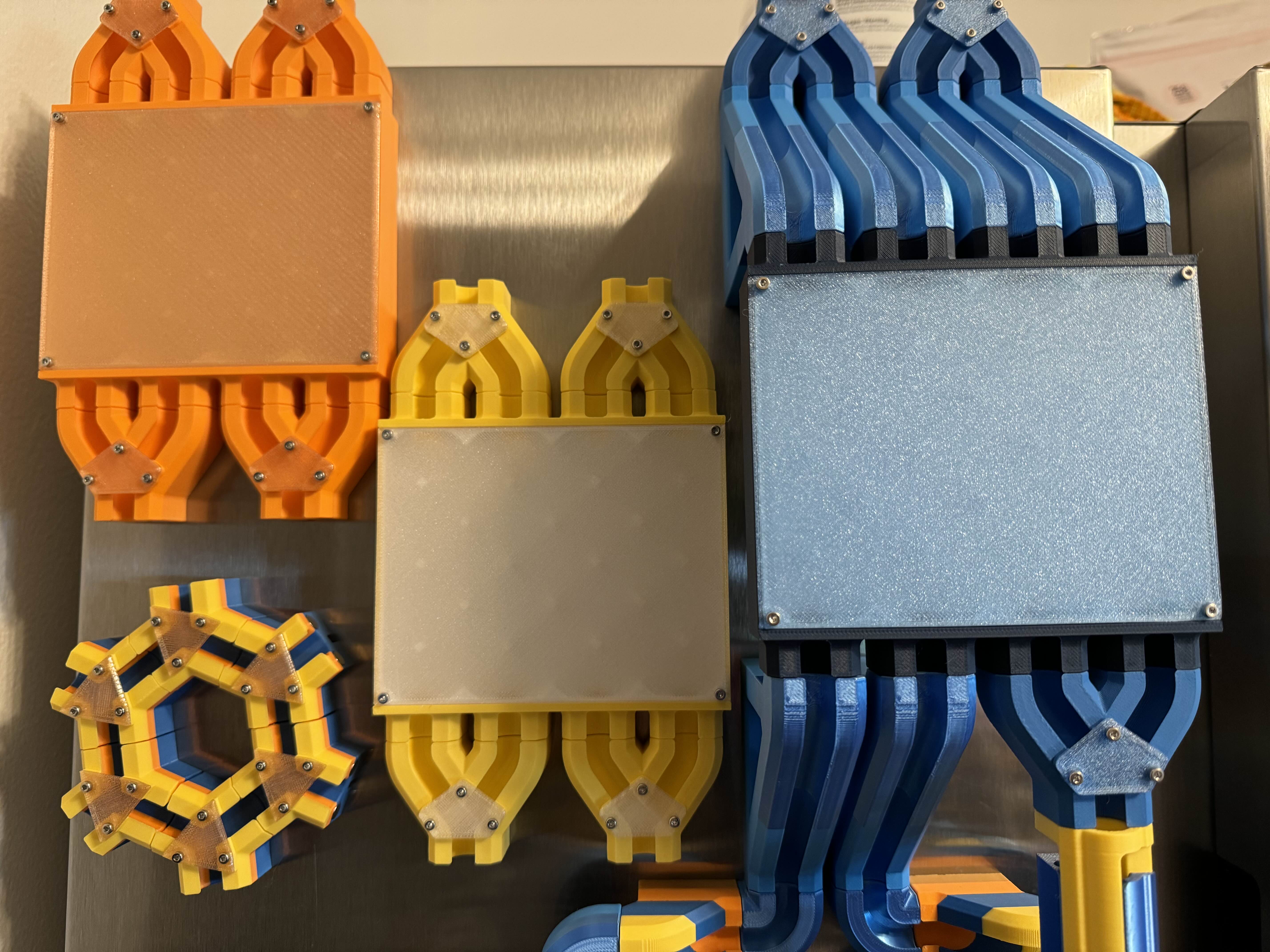

Printed cover plates on [CB], [<60] and [MD1] (user submitted by Akuna)

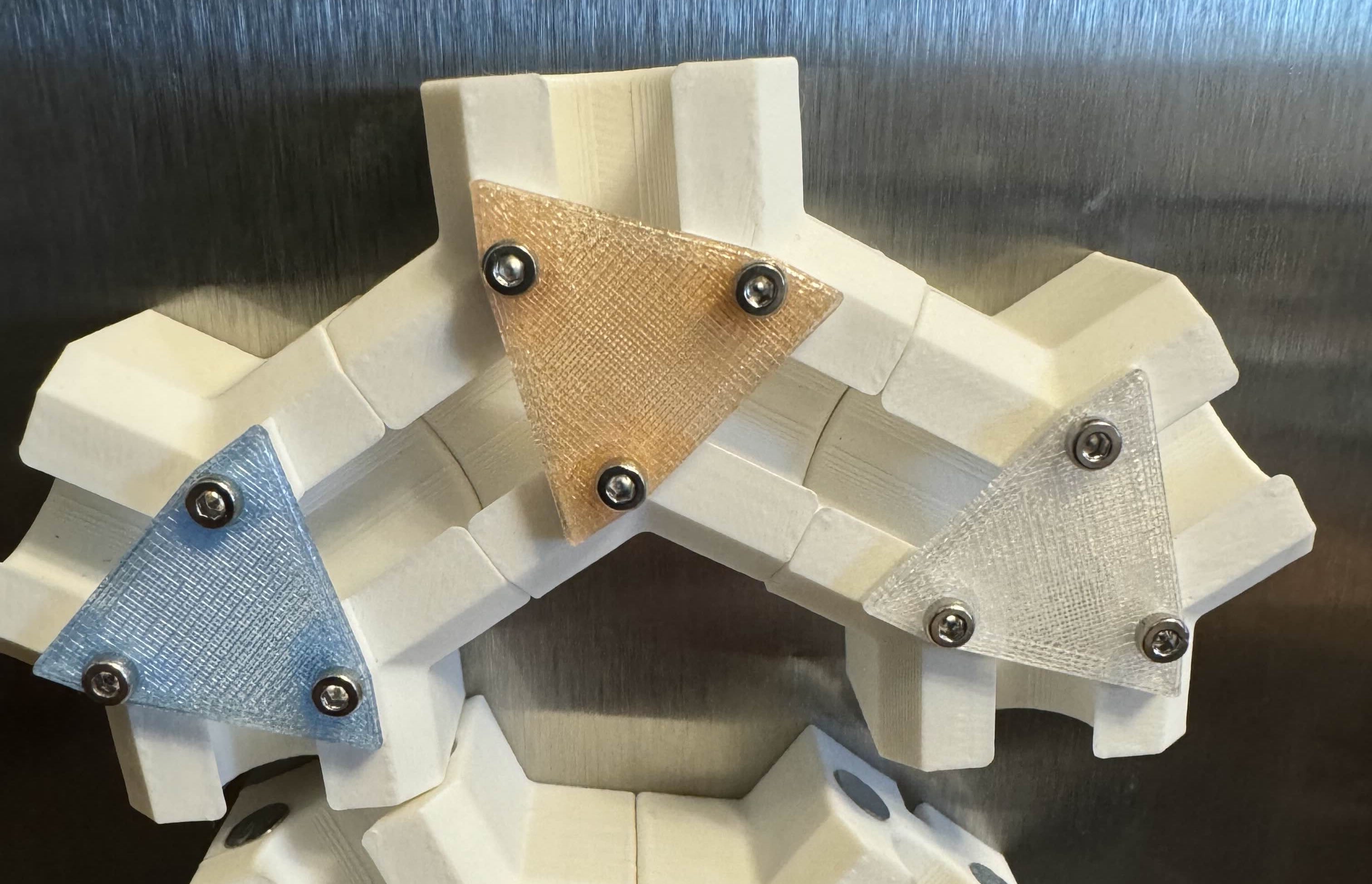

You can also use different shades of translucent PETG to create tinted cover plates as demonstrated in the image below.

Blue, Amber and Clear PETG cover plates from left to right (user submitted by Akuna)